Gritty Practical Leadership Book Five Star Review Try It on Amazon

Real Leadership Without the Gloss — Lessons That Last –Book Review Introduction Most leadership books fall into one of

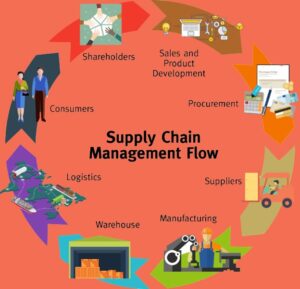

In the contemporary interconnected economic environment, the ability to bounce back at a supply chain goes beyond logistics efficiency and is contingent on technological adoption and the ability to strategize. The level of the supply chain focus is correlated with the increasing disruptive factors arising from natural disasters and political wars. The present paper discusses the technological elements and the active measures that are very important in the operation management of disruptions, specifically to the aspects of flexibility, openness and creativity.

Ostensibly, the development of globalization has put supply chains at the very center of economic activities while rendering them susceptible to numerous disruptions. In the earlier years, these interruptions would have been short-lived or even regional. However, with modern supply chains being just in time and integrated and interdependence, a trouble in one region can seriously affect the whole operation thereby causing disruption and increased costs. This inadequacy was made clear during the COVID 19 outbreak that also enforced the importance of a well-designed system capable of sustaining shocks and bouncing back from them within a short time.

The diversity of supply sources is a primary proactive tactic. An increased vulnerability to interruption arises from a heavy reliance on a single supplier or geographic area. Businesses can lessen the chance of a total stop in production or service delivery by establishing a number of suppliers in several locations. Strategic diversification should include a range of production capacity and delivery methods in addition to different suppliers.

Techniques for inventory management are essential for minimizing disruptions. Although lean inventory systems, which prioritize low stock levels to cut expenses, are widely used, they don’t allow much leeway for error during emergencies. Strategic inventory buffers, or inventories of essential goods or commodities, can act as a buffer against disruptions. To strike a balance between risk management and cost efficiency, these buffers should be dynamically modified based on real-time data and predictive analytics.

Building strong ties with important suppliers helps improve coordination and communication—two things that are essential in times of crisis. Creating structures for routine communication, collaborative risk evaluations, and emergency preparation with suppliers guarantees that everyone is on the same page and ready to move swiftly when necessary. When negotiating interruptions, this cooperative approach cultivates a sense of mutual reliance and trust that can be quite helpful.

For supply chain management, the combination of predictive modelling and advanced analytics is revolutionary. Businesses can predict possible interruptions with amazing accuracy by utilizing big data and complex algorithms. In order to identify hazards and suggest preventative actions, predictive models examine historical data, market trends, an

d environmental variables. Supply chain managers can plan for alternate sourcing strategies, optimize inventory levels, and identify bottlenecks well in advance of a disruption thanks to these technologies.

Supply chain resilience is undergoing a transformation thanks to machine learning and artificial intelligence. Massive data sets can be analyzed by AI-driven platforms to find trends and abnormalities that could indicate future disruptions. Over the years, machine learning algorithms have evolved, becoming more accurate in making predictions primarily because of their ability to learn new data. This integration of technology within the supply chain facilitates decision making in real time, thus enabling the supply chain to respond to the changes in circumstances quickly and minimize the negative impact of unforeseen contingencies.

The multifaceted security attributed to the use of blockchain technology enhances its applicability in supply chain management. The technology enhances supply chain efficiency because it enables a creation of an inclusive and unchangeable record of all the relevant transactions. Such technology is beneficial in the movement of goods, their verification, and even in the enforcement of laws. 4. Being Connected in Real-Time and the Use of IoT: The Internet of Things allows the availability of real supply chain monitoring thanks to the interconnection of sensors and other devices within a network. IoT systems enable the collection of real-time information concerning manufacturing, transport and even how much stock is available. This stream of data facilitates the prompt detection of any abnormalities such as delays in the process or production of substandard goods, and applicable measures are taken. In case of disruptions in operation, it is imperative to have the ability to monitor and react in real time to reduce the effects and ensure the smooth running of operations.

Developing a robust supply chain calls for a comprehensive approach that incorporates these components into a coherent plan, rather than merely putting individual policies or instruments into place. A thorough framework for disruption management is produced by the interaction of technical tools like advanced analytics, artificial intelligence, blockchain, and the Internet of Things with proactive strategies like supplier relationships, diversity, and inventory control.

Establishing a culture of constant adaptation and improvement is vital for organizations to make sure that their supply chains are not just ready for the difficulties of the present but also flexible enough to change in response to new threats. This entails investing in new technologies, reviewing and improving strategies on a regular basis, and committing to collaborative methods.

The capacity to establish and manage a strong supply chain is a crucial factor in determining an organization’s success in a time of historical volatility. Resilience is built on proactive measures including effective inventory management, diversity, and solid supplier connections. Technological solutions like blockchain, IoT, AI, and sophisticated analytics offer ways to improve responsiveness and flexibility. Businesses may handle disruptions more adeptly and maintain the continuity and effectiveness of their supply chains in an increasingly uncertain world by combining these metrics and instruments into a cohesive strategy.

Real Leadership Without the Gloss — Lessons That Last –Book Review Introduction Most leadership books fall into one of

A Masterclass in Leadership Through Real Stories Leadership Stories from the Corporate Jungle and Navy Deck Plates: Real Lessons,

Dr. Tom DePaoli CEO Apollo Solutions won an award for his book “Leadership by Storytelling: The Best Way to Learn Good Leadership Skills”,

Copyright © 2024 Dr. Tom’s Advice Blog | Powered by Dr. Tom’s Advice Blog